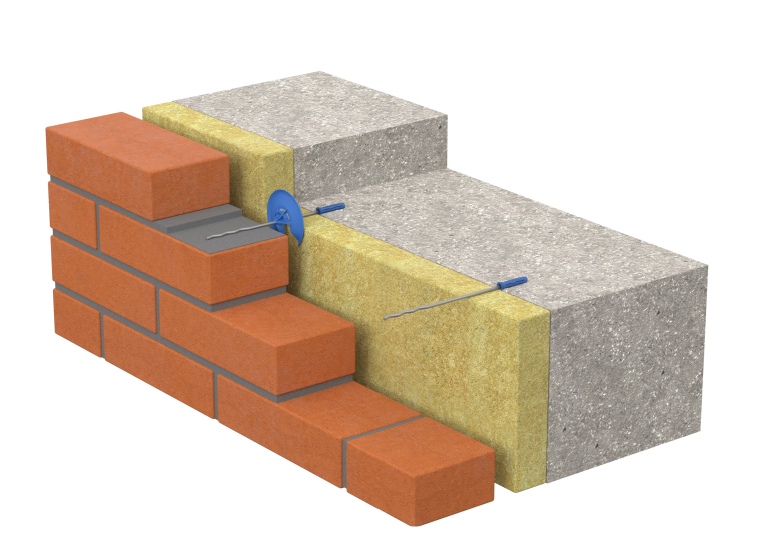

Wall ties and all other materials for anchorage the ventilated facadses should be made of stainless steel in the grade compliant with EN 1996-2.

All surface protected wall ties (galvanized, dipped in adhesive or cement paste) are imperfect. This is because during assembly and work in the masonry the protective layer can easily be damaged and the wall tie is corroded. This is a dangerous situation especially in the case of galvanized anchors where an electrolytic corrosion is produced instantaneously at the contact of iron and zinc.

The façade is loaded with wind pressure and suction therefore the anchors must have high compressive and tensile strength. At the same time they should be made of a material that is flexible enough to allow separate operation of the façade and the main wall. Too rigid anchors may lead to cracking of the façade (during sun heating they will not allow the façade to move relative to the internal walls). Therefore the anchors can not be too thick. The recommended diameter is 4 mm. At high wind loads simply the number of anchors per 1 m2 of façade increases.

The number of anchors per 1 m2 depends on the wind pressure and suction in a given zone, the elevation distance from the load-bearing wall, wall surface, insulation and other factors and should be each time calculated by the constructor. In 99 cases out of 100 the number of 5 pieces / m2 is correct. In this case, the anchors should be placed every 50 cm in the horizontal spacing and every 40-45 cm in the vertical spacing, so that they “pass” each other. In addition linear wall ties (3 pieces per linear meter) are placed around the openings (window and door).

Wall ties can be divided into two groups:

Wall ties to fix into the joints

They are intended for inserting into the mortar during the construction of the inner wall. Depending on the technology of inserting the internal wall, two types of wall ties are used:

Both groups of wall ties are best suited for cases where the height module of the load-bearing wall elements is a multiple of the height of the façade bricks (or is simply the same). The main advantage of such wall ties is very simple assembly. The disadvantage – the need to bend in case when the welds of both walls do not overlap each other.

Wall ties to fix in an existing structural wall.

They are used in several cases:

– putting horizontal lines on the wall (measured in such a way as to coincide with the welds of the future façade wall) in a spacing of 45-50 cm

– drilling holes on these lines every 50 cm for future wall ties

– inserting into the holes of dowels suitable for a given type of wall (different dowels are used for concrete, ceramic or foamed concrete walls). Does not apply to NGK. The NGK wall tie is designed for mounting directly in the foamed concrete without use of a dowel,

– screwing in or hammering in the dowels (screwing or hammering devices may be helpful for this purpose).

– Wall ties should be anchored in the supporting wall to a depth of approx. 4 cm while in the elevation layer approximately 5-7 cm. (see drawing next).

Accessories for wall ties

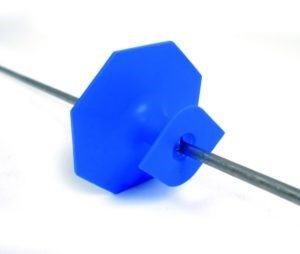

Retaining clips:

Retaining clips are made from plastic (polyethylene). They stabilize the insulation layer in the cavity wall so that it adheres to the structural wall. They also drain condensate away from insulation which is especially important when using mineral wool. Another function of the clip is to give a minimum two-centimeter air gap (KOMBI disc).

Types of retaining clips:

| NAME: | KOMBI | LIP | ECO |

| Diameter: | 3,6 – 5,0mm

|

3,6 – 4,2mm |

3,8 – 4,2mm

|

| Description: | Najbardziej uniwersalny krążek. Bardzo prosty w montażu. Nadaje się do wszystkich typów kotew. Pustka powietrzna nie może być mniejsza niż 2,2cm | The best clip. Constructed in such a way that even after deflecting the wall tie, it holds warming with its entire surface. | The most popular clip. At its small thickness, it has a profile that drains condensate water vapor (drip). Used especially on investments, where we suppose that the air gap can be less than 2 cm. |

| Advantages /

Disadvantages |

+ easy assembly

+ drainage + gives air gap – after deflecting the wall tie insulation layer is not tight enough |

+ the best drainage

+ regardless of the bending of the wall tie insulation is retain+ gives air gap – fastened with a latch |

+ very easy assembly + good price + low thickness – not the best insulation retaining, especially when bending the wall ties |

In our offer we have several types of pressure pins, used depending on material of structural wall (eg reinforced concrete, ceramics, cellular concrete, etc.)